Our Products

We offer various products to our clients and always ready to customise the same as per our clients requirement.

Data Center The determination of cooling requirements for IT systems can be reduced to a simple process that can be done by anyone without special training. Expressing all measures of power and cooling in Watts simplifies the process. A general rule is that a CRAC system rating must be 1.3 times the anticipated IT load rating plus any capacity added for redundancy. For larger data centers, the cooling requirements alone are typically not sufficient to select an air conditioner. Typically, the effects of other heat sources such as walls and roof, along with recirculation, are significant and must be examined for a particular installation. The design of the air handling ductwork or raised floor has a significant effect on the overall system performance, and also greatly affects the uniformity of temperature within the data center. The adoption of a simple, standardized, and modular air distribution system architecture, combined with the simple heat load estimation method described, could significantly reduce the engineering requirements for data center design. Comfort Airconditioning

With comfort air conditioning, the focus is on people. Our technology is based on the respective requirements of a project, but simultaneously always looks for the most efficient method with the lowest consumption of energy. Cold Aisle Containment Systems

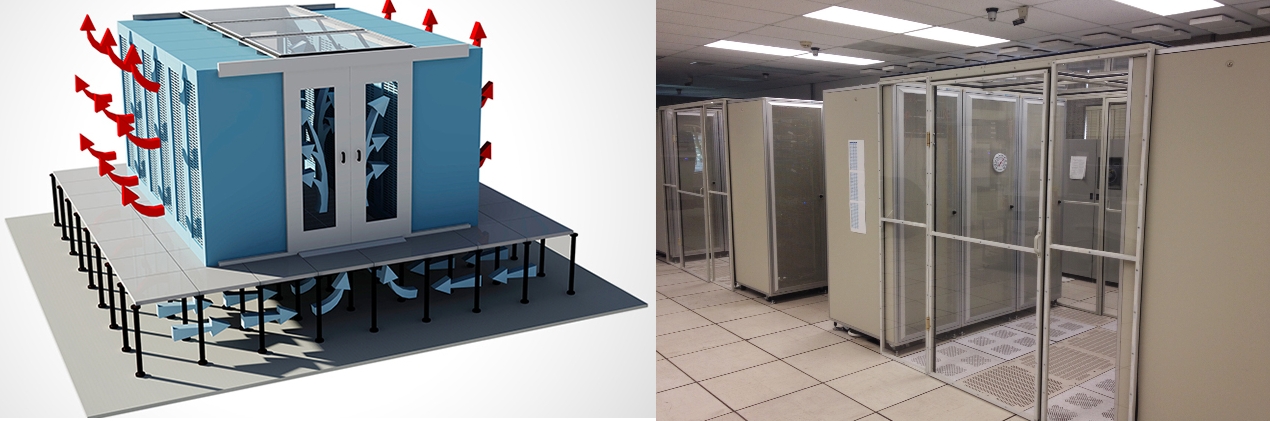

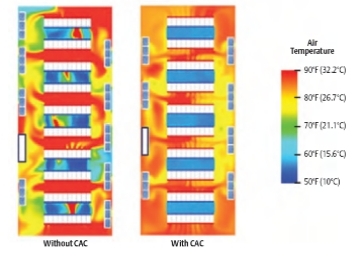

Reduce energy consumption with cold aisle containment by eliminating the mixing of hot and cold airCold Aisle Containment (CAC) Solution isolates a rooms cold air supply and confines it to an entirely closed off area targeted at cooling IT equipment instead of the room. With the fronts of cabinets facing each other as they would in a typical cold aisle design, the addition of doors on each end of the aisle and ceiling panels across those adjacent cabinet rows creates a complete segregation of hot and cold air. Cold Aisle Containment-AdvantagesIt increases the cooling capacity and energy efficiency of the cooling unit ensuring that the return air temperature to the cooling unit is high. Second, the increased capacity, together with the separation of hot and cold air, makes it possible to cool higher heat loads per rack. Additionally, with hotter air returning to the cooling coil, the cooling capacity available for cooling the sensible heat generated by the electronic equipment is increased. Under these conditions the cool supply air temperature is almost always above the dew point. Consequently, there is minimal moisture removal (latent cooling), which saves energy by allocating more of the total cooling capacity to dissipate the 100 percent sensible electronic heat load. The minimal latent cooling also increases the total energy efficiency because of less demand for re-humidification of the air.

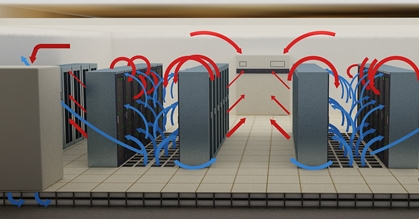

Central Plant Energy EfficiencyRecommended server inlet temperatures range between 64.4 degree F and 80.6 degree F. Chillers typically produce chilled water around 45F degrees and inlet air around 58F degrees. This disparity exists, again, because of air mixing within the data center. As inlet air and exhaust air interact, the hope is the resulting inlet temperature falls somewhere in the recommended range. Through containment, a user can eliminate this uncertainty. If he desires a 68F degree inlet temperature, perhaps he can achieve it with 58 degree F water. The warmer the water, the more efficient the chiller operates. The current economic climate may delay an organizations ability to build a new data center. As a result, they will demand more uptime and more computing capacity from their existing facilities, while the industry encourages conservation and sustainability. Cold Aisle Containment proves an economical way to achieve both objectives The premise of cold aisle containment, though simple, can improve cooling performance. Data Center Hot Aisle/Cold Aisle ChallengesEven at minor heat loads, there are challenges associated with hot aisle and cold aisle. Some of them include:-

Data Center with Bypass Air problems (mixing of hot and cold air) A main cause of power loss. As rack densities inevitably climb, the challenges above become more severe. The infrastructure struggles to deliver a sufficient volume of cool air to the equipment and to move exhaust air to the air handlers. As its forced to deliver colder air at a greater CFM, the cooling scheme consumes more energy from the fans through the pumps, down to the chiller. And even under minimal loads, the efficiency of these systems is suspect. PVC CurtainsCold Aisle Containment can be done using Flexible Polyvinyl Chloride (PVC) anti-static fire retardant PVC curtains which are hanged on either Aluminum/MS brackets fixed to ceiling or Assembled Aluminum support frame in overlapping manner for improved air sealing.

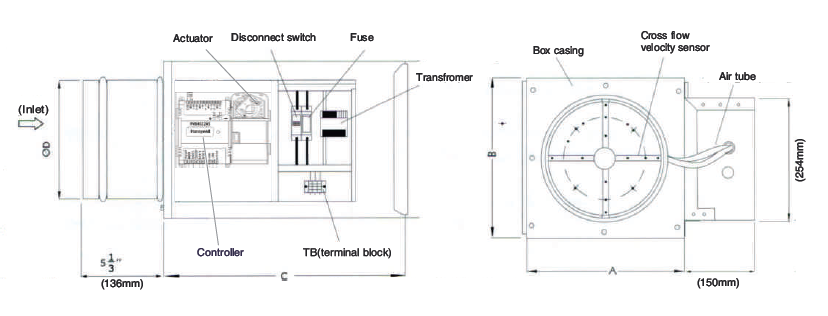

Aluminum Sliding Doors, Blanking Panels & Top Roof PanelsEasy to assemble Dual Sliding Door (Black anodized Aluminum Extruded Profiles & Transparent Acrylic Plexi Glass Fire retardant ULV-0 Sheets) is an ideal solution to end-of-row hot or cold aisle containment in any data center. Doors are available in standard sizes as well as custom sizes to fit under overhead obstructions or other sizing requirements. There are no obstructions on the floor of the aisle that could impede access of a person or trolley. Easy to assemble Dual Sliding Door (Black anodized Aluminum Extruded Profiles & Transparent Acrylic Plexi Glass Fire retardant ULV-0 Sheets) is an ideal solution to end-of-row hot or cold aisle containment in any data center. Doors are available in standard sizes as well as custom sizes to fit under overhead obstructions or other sizing requirements. There are no obstructions on the floor of the aisle that could impede access of a person or trolley. Customized Roof Panels (Black anodized Aluminum Extruded frame profiles with Clear transparent Fire retardant rigidULV-0 acrylic insert) to enclose the open top portion of the aisle with support taken from the false/actual ceiling. VAV We understand how important it is to have a truly independent Variabl Air Volume (VAV) terminal. A VAV Terminal that is independent on the variable air volume terminal design and on the DDC controller that makes the box work, i.e. an independently open VAV direct digital controller that can be interfaced to any Building Automation System (BAS) in the field. The networking requirements of VAV terminals and the Building Automation Systems of intelligent buildings have left the markets disillusioned int the past decade. Systems are unable to communicate with each other, as different BAS suppliers have their own proprietary gateway integration design. What we offer?The single duct Variable Air Volume terminal unit- VAV 5000 series combine the latest in sheet metal technology, and the state-of-the-art multi-point differential pressure sensor and a truly open system LonMark/BACnet DDC Controller, to give a pressure independent box. VAV boxes are also compatible with DDC that are available in the market. We have in-house testing facility ensures that all boxes coming out of the factory are fully calibrted and tested to match the controller of the individual box size. Each box goes through a thorough quality control procedure that allows no error and makes the box a truly working box int the field. This controller can be networked onto any LonWorks / BACnet BAS system or used independently as a standalone operation. VAV 5000 It includes:

Air Volume Ranges VAV terminals are designed for use in low or medium pressure duct system. They are available with several available accessories. Optional accessories include hot water reheat, electric reheat, extended casing and multiple outlet plenums. Controls can be factory fitted and wired by trained personal. Wiring schematics are affixed inside the control enclosures for field reference. The VAV terminals are widely used in many HVAC in all types of buildings. Controller & Wall Module VAV Controller - Spyder PVL/PVB range VAV controller Wall module - TR4x Spyder VAV Controller

Tr4x Wall Module

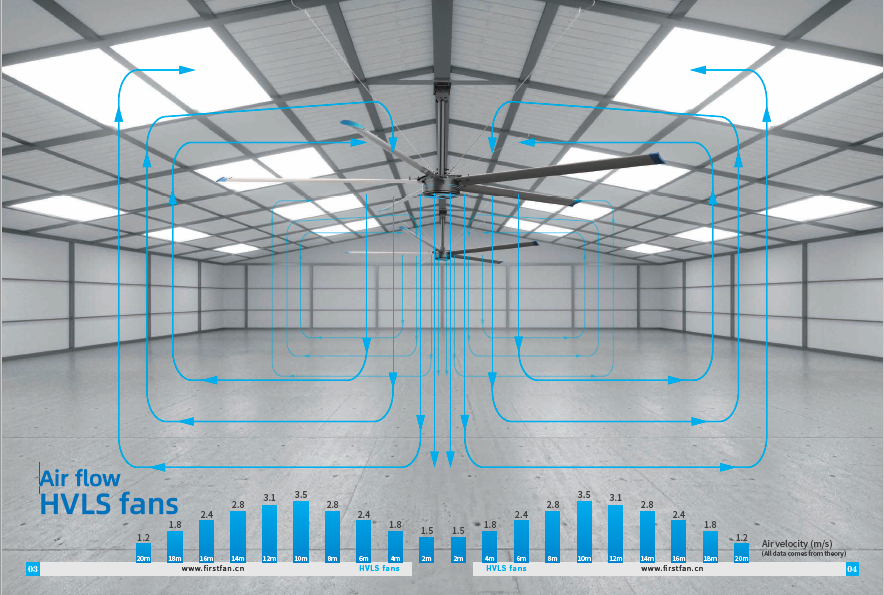

VAV Box PAckage  FirstFan - HVLS Fans FSD-FC Series are available in five sizes ranging from 12ft- 24ft equipped with PMSM motor. It is a perfect solution to ventilation & cooling in large places, such as factory workshop, warehouse, church,commercial buildings, supermarkets, library, lobbies, barn, etc. It brings gentle breeze at low rotational speed. Large Coverage : The largest area it can cover is 1,500m2. The highest air volume can be up to 13,900m3/min. Energy Saving : Compared to traditional multiple wall mounted fans and air conditioners,HVLS fans can reduce by 30%-50% energy bills. Human-body cooling : HVLS fan will make people feel 5-8 Celsius temperature reduction. Gentle breeze : Unlike traditional high speed fan, HVLS fan creates gentle breeze which makes people feel comfortable. Easy installation : Its not necessary to damage your beam structure. The minimum vertical height of installation space can be 0.86M. Technical Specification & Brochures

|